History

Our History

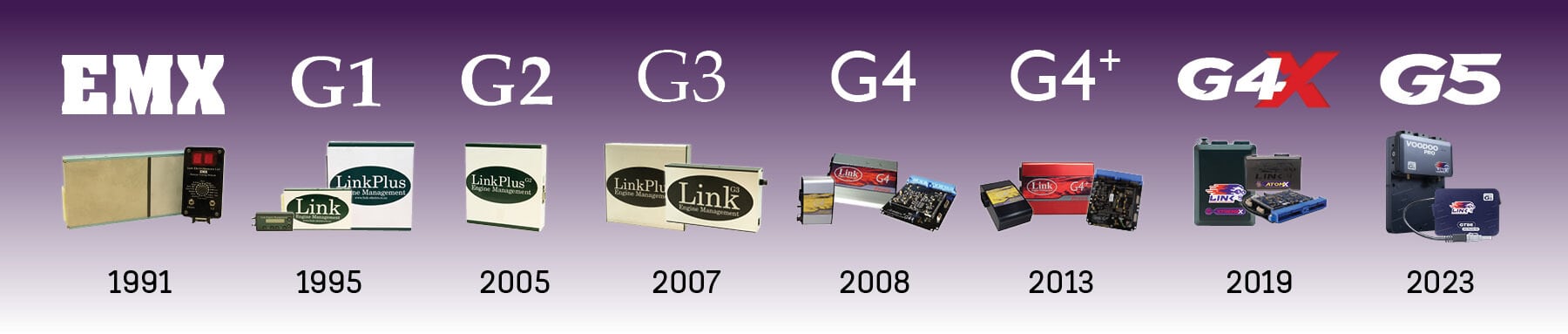

Our story begins in Christchurch, New Zealand, the year: 1991. A group of passionate engineers set out to develop the world’s best race technology. Their vision was to put power, performance and reliability in the hands of drivers and teams, and to push themselves and their technology as far as possible.

Fast forward thirty years and what they started has grown into a world leader in Engine Management Technology with products sold in 70 countries, by over 1,500 dealers and tuners.

This is Link’s story so far...

In 1995 the Possum Link, a joint project between Link Engine Management and New Zealand rally legend Possum Bourne, was launched. The Possum Link was our first ever Plug and Play ECU, designed specifically for Subaru WRXs.

In 2001 the LEM was followed up by the LinkPlus, also sporting the classic green and white case. The LinkPlus had 8 injection drives, 9 ignition drives, 2 temperature inputs, 3 analogue inputs, 2 digital inputs and 16 auxiliary outputs plus knock control.

In 2001 PC Link was released to run the LEM and LinkPlus. PC Link replaced the need for hand controllers.

In 2005 the next generation of ECUs, the LinkPlus G2 was launched, being the last to wear the distinctive green and white case. The Linkplus G2 8 injection drives, 8 ignition drives, 2, temperature inputs, 4 analogue inputs, 3 digital inputs and 11 auxiliary outputs. It was the first LinkECU to use the ST10 16-bit microcontroller.

In 2007 the third generation of ECUs, the G3, was released with a new silver and black colour scheme designed to fully maximise the ST10 16-bit microcontroller that had been introduced a

In 2008 LinkECU also launched the Premium Vi-PEC V44 and V88 range of ECUs.

In 2011 Link Electrosystems Limited changed it’s name to Electronz Limited.

In 2013 the G4 range was upgraded to G4+. The G4+range of ECUs featured for the first time: OBDII, more GP Tables and 25 Channels of Data Logging, plus Internal Knock Control and E-Throttle.

In 2015 the G4+ and Vipec i44 and i88 ECUs received brand new die-cast enclosures, black for G4+ and blue for Vi-PEC.

In 2016 Link Engine Management underwent a major rebrand, changing from the time-honored silver and grey oval branding to the exhilarating purple and red branding.

2022 was a big year for Link, releasing our first ever PDM, known as the Razor, and launching the new G5 platform, with the technology to be used in the new Voodoo Pro ECU, which was then sold throughout 2023.

In 2024, the G5 range was added to with Plug-in ECUs, such as the GT86 Plug-in.

Company Location

Link's Head Office has been located in Christchurch since the company's inception in the 1990's. The premises have been shifted around as a result of incredible growth and also the devastating Christchurch earthquake in February 2011. The unique R&D building (the Lyttelton Road Tunnel building) was deemed to be irreparable after all the earthquakes and was demolished in mid 2013.

Nowadays, Link Headquarters is still located in Christchurch and we are very proud to stay close to our roots here. We have a large workshop purely set-up for our own product development and testing, plus the race track (Mike Pero Motorsport Park) is conveniently just down the road for when we need to test something on the surface.

Over the early years we fulfilled all orders from our New Zealand Dispatch warehouse. Around 2010 however, we opened a sales office and dispatch plan based in the United Kingdom to service UK and European Sales.

In 2017, Link opened an office and logistics center in the United States as well.

We now have offices, staff and warehouse locations all around the world - including but not limited to - Birmingham, Brisbane, Dubai and Detroit.