Engine Protection Features

Engine Protection features

We all know that high-performance builds can get expensive, protecting that investment is just as important as chasing power.

When you’re pushing an engine to its limits, even a minor issue can snowball into major damage. At Link, we believe that prevention is just as critical as performance — that’s why every ECU and accessory we build is designed with robust protection features that step in before things go wrong.

Link Engine Management’s innovative approach to tuning gives you amazing flexibility and control over how you implement your safety strategies. Use runtimes coming from any sensor to cut power, activate limp modes, switch fuel maps, or trigger warnings before a problem turns into a failure.

Below you’ll find an overview of our standard and advanced protection features, along with how each one helps extend engine life and keep your build safe.

Core Protection Systems

Temperature Monitoring & Response

Our ECUs constantly track all available sensor data from coolant and oil temperature to intake air temps and more. If any reading exceeds your defined safety limits, the system can respond immediately with actions such as reducing power output, enabling a limp mode, or triggering an alert, all before serious damage occurs:

-By enriching your Air Fuel Ratios

-Pulling ignition timing

-Reducing boost or torque

-Entering a fail safe

-Using hard or soft cuts to respond instantly

-or shutting down the engine

These methods can help prevent damage from detonation, overheating, or oil starvation.

Oil & Fuel Pressure Protection

Low oil or fuel pressure is a serious risk to an engine.

Oil Pressure Monitoring: You can customosie minimum safe pressure levels, which you can define not only as a single value, but by a table with customisable axis, such as RPM, load or Temperature. The system can warn the driver, apply soft or hard cuts to a given rev limit, or even shut down the engine to prevent catastrophic failure.

Fuel Pressure Monitoring: Detecting a drop in fuel pressure helps avoid lean-running conditions, our fuel model will compensate for fuel pressure when set up. Detecting a sudden fuel pressure drop may point to failures, and intervention can prevent damage from running too lean.

Knock Detection & Control

Detonation (knock) is one of the quickest ways to damage an engine. Our knock system can detect the onset of knock and automatically adapt, trimming ignition timing, boost, or fuel until the knock subsides. This real-time correction greatly reduces the risk of bearing, piston, ring, or head damage.

Fuel Management

High-resolution, highly customisable load and RPM based fuel mapping with trims for temperature, gear, and more. Our advanced fuel modeling can make use of injector dead times, short pulse width adders, injector flow compensation based on voltage, and fuel pressure, supporting precise injector control for power and longevity. One of the hallmarks of our system is the total customisability given by being able to set your own axis on any of the fuel or fuel compensation tables. (Also see Flex Fuel & wideband control below.)

Wideband O₂ / Air-Fuel Ratio (AFR) Monitoring

Using our closed loop lambda, you can track AFR in real time and apply corrections to keep you on target with your fueling. We also have long term fuel trims, which can help you improve your fuel map over time. Using Lambda also allows the use of tuning tools such as our mixture mapping. These tools can be used on their own as a form of self tuning, to help you easily perfect your fuel mapping.

RPM Safeguards

Over-Rev Protection / Rev Limiter

Every high-performance engine benefits from a rev limiter. This feature caps maximum RPM, protecting against mechanical over-speeding (e.g. valve float or connecting rod failure).

MAP Limit

Set up with in the same way as the general RPM limiter with all the options for customisation, but based around manifold pressure. Allows you to bring in a different style of limiter when overboosting for example.

GP RPM Limits

GP RPM Limits provide the user additional configurable RPM limits, which provide you the ability to specify conditions not covered by the standard RPM Limit. A common use for this might be an oil pressure related RPM limit for example.

System Voltage Limit

This is designed to protect the Link ECU and other electronics in the event of a faulty charging system or incorrect jump starting. If the system voltage exceeds the Shut Down Voltage, the ECU will stall the engine.

Multiple Rev Limiters

Some Link systems support multiple rev limiters for different operating modes—such as:

A softer launch mode limiter + a more conservative burnout limiter + a full power, max RPM limiter

This flexibility ensures that the engine is never pushed beyond safe rev limits under any driving condition.

Speed Limit

Useful for pit lane speed limiting, can be enabled by any parameter of your choosing, with all of the same customisability of our other limiters

Fail-Safe & Fault Handling

Fail-Safe Strategies

Should a critical sensor (such as the crankshaft position sensor) fail, the ECU can shift into a reduced-power or limp mode. This allows you to drive to a safe location (or a repair shop) rather than being stranded with a sudden failure.

Combined Protections for Engine Safety

All of the above systems contribute to a layered, comprehensive protection strategy. From rev control to knock mitigation, pressure monitoring to thermal intervention—each layer helps preserve your engine in abnormal conditions.

However, it's vital to remember: an EMS (Engine Management System) is only one part of the equation. To maximize protection and longevity you must also:

Perform routine maintenance (oil changes, filter replacements, fluid checks)

Inspect mechanical systems (cooling, intake plumbing, wiring)

Use quality supporting hardware and tuning practices

Drive responsibly — pushing an engine beyond its design limits is still risky, even with protection systems in place

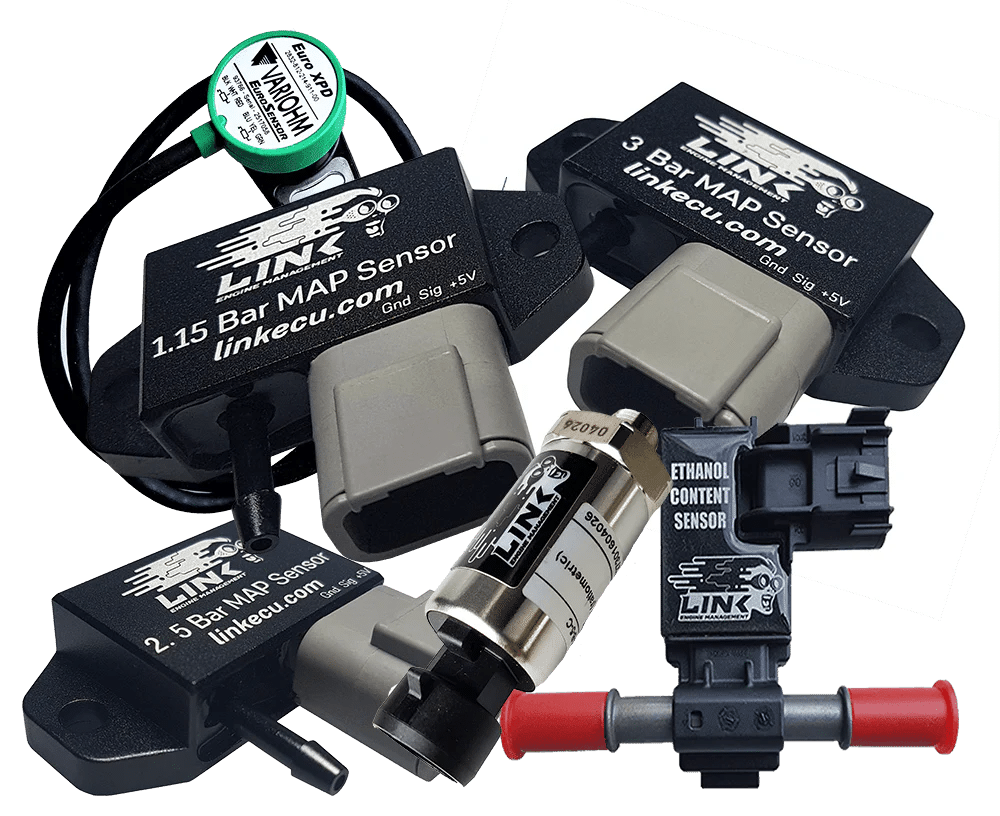

Must-Have Accessories for Protection

In addition to protection features built into the ECU, a few key sensors and accessories are essential for turning theory into reality. Here’s what we recommend:

-

Temperature sensors (coolant, oil, intake air) — feed live data to protection logic

-

Oil pressure sensors — critical for detecting lubrication issues

-

Fuel pressure sensors — guard against starvation or pump failure

-

CAN Lambda / Wideband O₂ sensors — allow the ECU to monitor air/fuel ratio and trigger fail-safe when it goes lean

-

Knock sensors / KnockBlock — enable detonation monitoring and real-time tuning feedback

-

Voltage and system monitoring modules — support detection of electrical anomalies

-

CAN expansion modules, to integrate additional sensors without overloading ECU I/O

With these devices in place, your ECU can make informed decisions, transitioning the engine to safe modes or alerting the tuner when limits are approached or crossed.